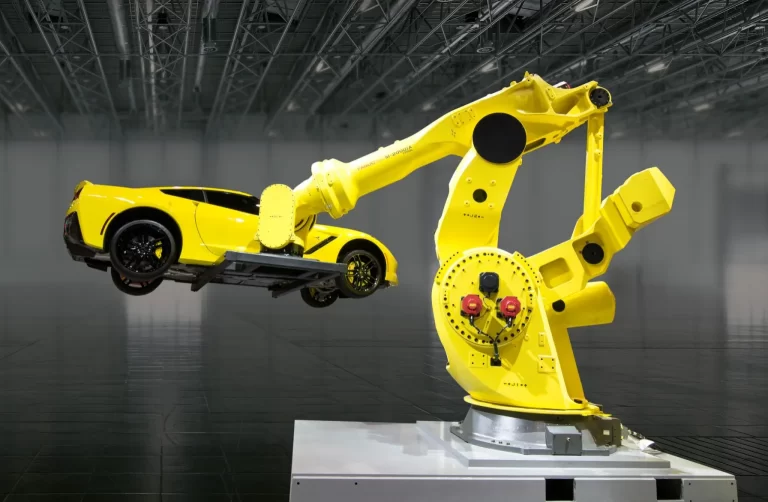

Robotic arms have revolutionized manufacturing by mixing safety, precision efficiency, and other factors that were previously unimaginable. Robots are mechanical marvels that are now essential to many industries around the world. They were invented in order to lower operating costs as well as keep high standards of quality. Incorporating robotic arms into the production lines allows manufacturers to not only reduce costs but also improve worker safety and efficiency. Find out how these robotics have changed the industrial landscape.

Image credit: automatedsolutions.com.au

The primary force behind the global surge in robotic arm adoption is cost efficiency. Factory owners are constantly under the pressure to decrease workplace injuries, limit production mistakes, and minimize the amount of waste. A robotic arm addresses these challenges head on. As opposed to humans, robot arms perform repetitive tasks with pinpoint accuracy which eliminates costly errors and reducing the waste of raw material. For instance, in high-volume industries such as automotive manufacturing, robot arms execute exact welding and part placement making sure that the assembly is perfect each time. This accuracy translates into substantial savings as less defective products mean less rework and wasted.

Safety is another important aspect of the robotic arm revolution. Human workers are at risk when performing many manufacturing tasks, including working with hazardous materials or using large machinery. By utilizing robot arms companies can eliminate workers from potential danger zones. This lowers the risk of injury at work. A robotic arm, constructed as a kinematic string of moveable joints, is modeled after the function of a human arm but without the risk of physical harm. The machines come with robotic hands or end-effectors that can be programmed. They can perform tasks like grasping, spinning and welding, in conditions that would make it dangerous for human beings.

The range of applications for robot arms is a game-changer in many industries. Robots are able to adapt to many different tasks, from assembly for automobiles to electronic production. They can perform complex operations that require unmatched precision, which includes painting and tending of machines. When it comes to warehousing robotic arms have revolutionized palletizing, making it easier to load merchandise onto pallets with precision and speed. Automation does not just increase efficiency but also increases reliability since robot arms are able to be productive without fatigue.

The development of cobots (collaborative robots) that interact with human employees is one of the most exciting advances in this area. Unlike traditional industrial robots confined to isolated cells. Cobots fitted with robotic arms have been designed for a safe, seamless interplay with humans. A cobot’s robotic hand can be utilized for difficult lifting tasks and repetitive tasks in factories, so that human workers can free to focus on more difficult tasks. The collaboration improves productivity while also ensuring a safe working area, since cobots are trained to stop or change their actions if a person is within the vicinity.

Robotic arms have a profound influence on the modern production, and not only regarding safety or efficiency. The capability of robotic arms to accomplish tasks with incredible precision including welding, material handling, or assembly have made them indispensable in industries which place safety at the forefront. For instance, in automotive manufacturing, a robot arm is able to rotate and move components during assembly, ensuring flawless alignment, without the intervention of humans. Robot arms can also be used in electronics to take care of delicate components. This reduces damage, and enhances output quality.

As industries continue to grow with the advancement of technology, the need for robotic arms will continue to grow. Their capability to reduce cost, increase safety and adjust to different jobs makes them a cornerstone of manufacturing’s future. Robot arms that blend modern technology with human imagination They are not just tools as much as they are partners in progress. They fuel innovation and transform how the world is built.